Regatta Wharf

Date Built: 2000

Architect: Moore Ruble Yudell / Travis McEwen Group

Solander, Edgewater, Watercrest, Eventide. Buildings range from 7 to 15 storeys 143 apartments. Overlooks Pirrama Park, Elizabeth Macarthur Bay, Johnstons Bay. Site of CSR low pressure boiler station and coal silos.

Regatta Wharf

1880 - 1950

1880

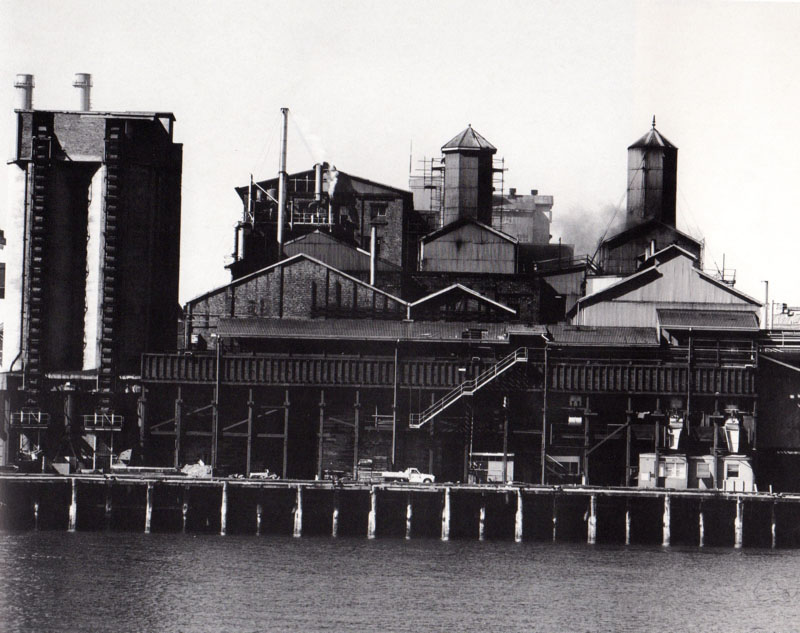

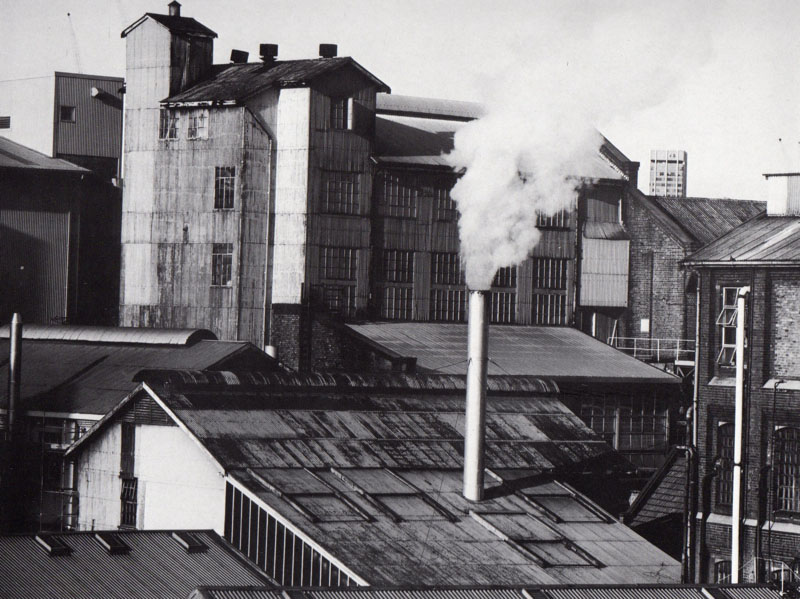

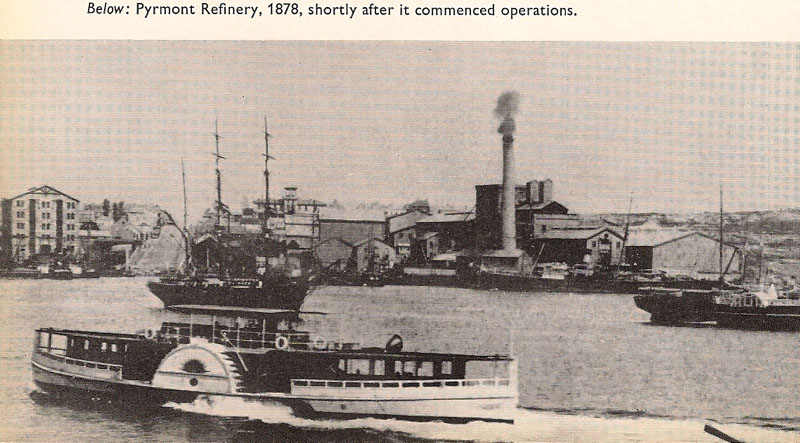

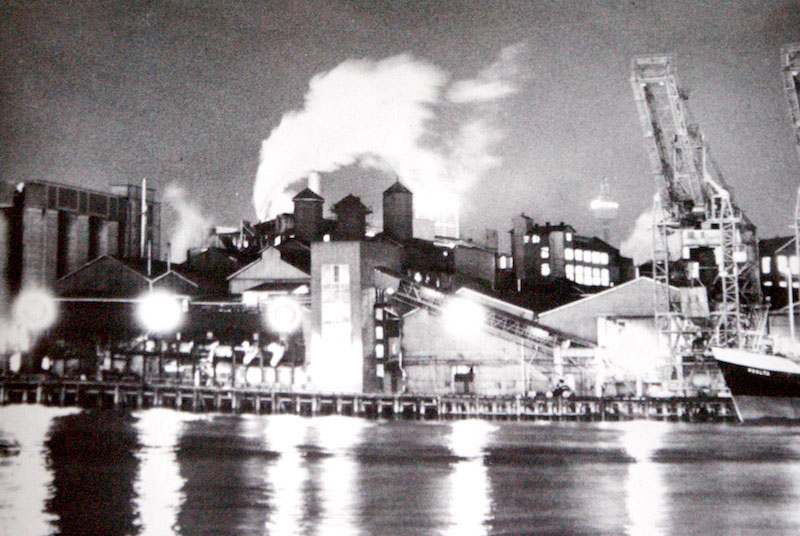

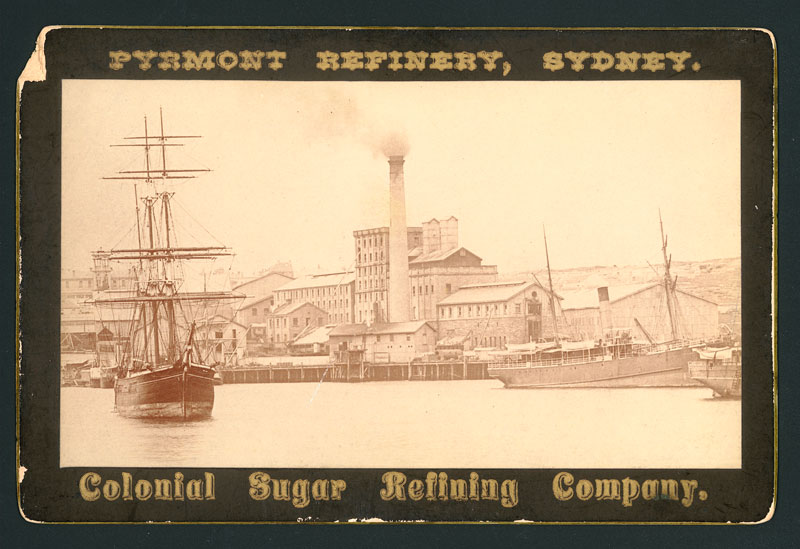

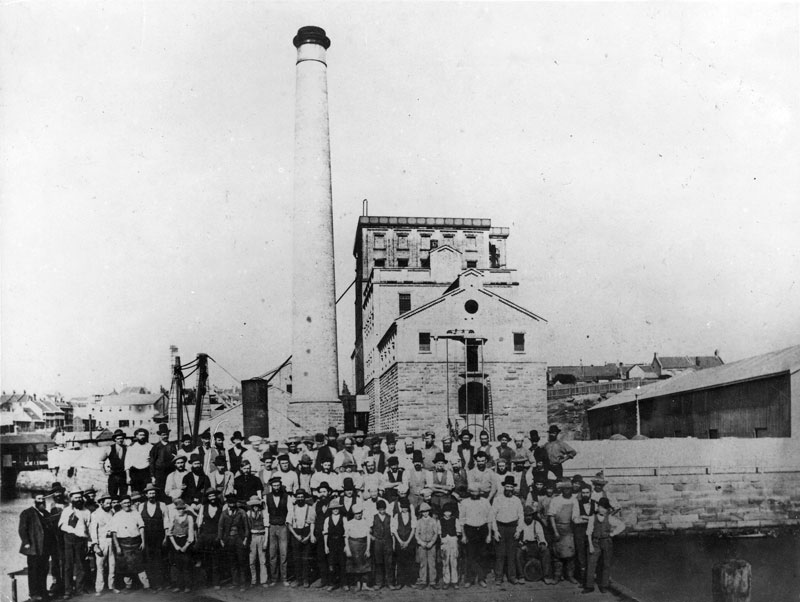

Drawn by Elizabeth Macarthur Bay and its anchorage, CSR’s Managing Director Edward Knox bought land and built a refinery in Pyrmont. Elizabeth Macarthur Bay was the focal point: here raw sugar from Queensland and Fiji was unloaded into the present Reflections site (East Wharf), and coal was shipped in to silos on the present Regatta Wharf. The refinery itself straddled what is now Refinery Drive between Regatta Wharf and Fleetview. The refinery building occupied all the ground between the silos and the packing station: and behind the coal silos rose the distinctive three turrets of the char end.

The wharves fronted such deep water that large vessels moored at the docks to unload. Eventually so many ships moored here that a new jetty (Free Wharf) was built, doubling the berthing capacity of the Bay.

The complex opened in 1878, shortly before European mass production of beet sugar undercut all sugar prices. CSR’s survival was threatened, so scientists and engineers were recruited to modify and improve processes, and the new Pyrmont refinery – already at the cutting edge of refineries – began a restless series of modernisations.

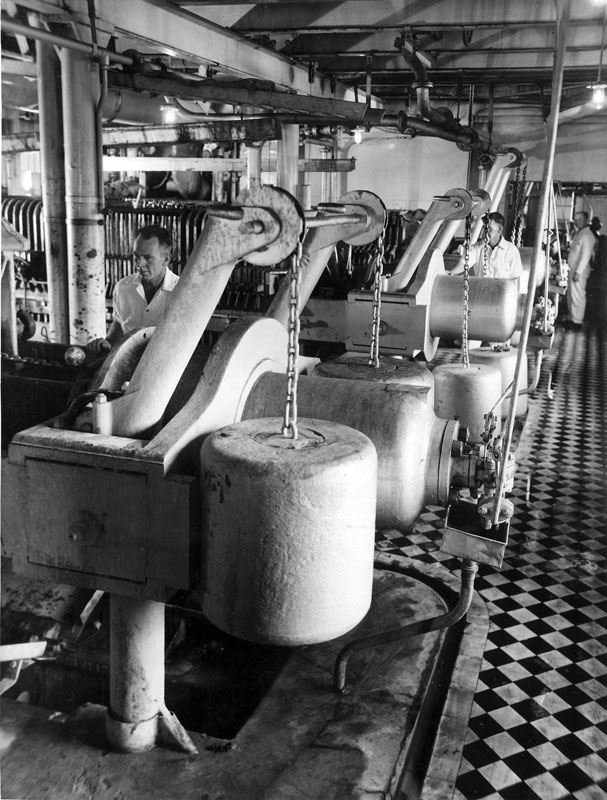

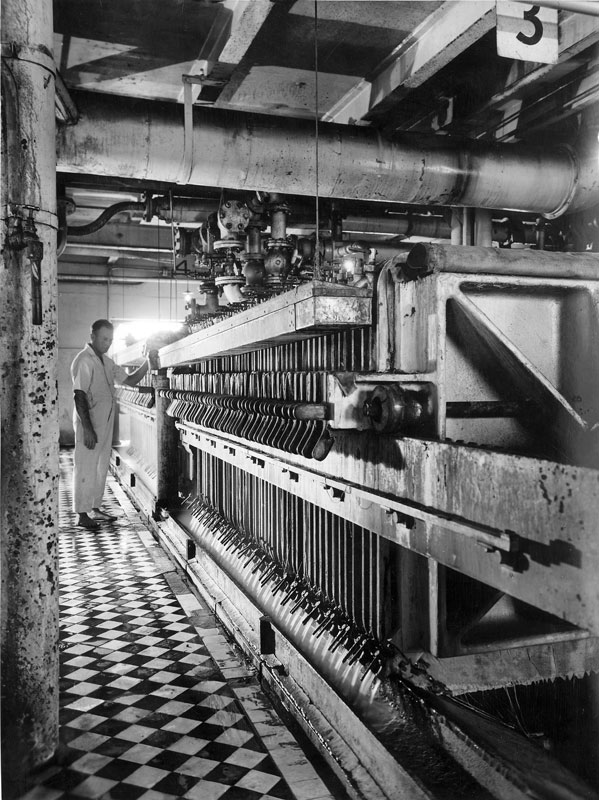

Raw sugar (98% sucrose) must be refined (to 99.9%) to create crystalline white sugar and the other forms (syrup, treacle, molasses, tablet) in which sugar is sold. Water, ash, organic matter and other sugars are removed to purify the product and prevent its deterioration. These impurities are small but elusive: they require hot-water washing, adding and removing lime, carbon dioxide and bone charcoal, filtering, boiling in a near-vacuum, warm air drying and sieving.

All these processes made huge demands on power. CSR produced its own. The present Elizabeth was where most of that power was generated in high pressure boilers, while a low pressure boiler also turned coal from the silos on the present Regatta Wharf into steam power.

1910-1950

When the Pyrmont complex expanded from sugar production to distilling (from 1901) and caneite (from the 1930s) the generation of power became even more important. The war-time production of armaments added to the urgency of preventing any interruption of the power supply. The system was – and remained – one based on steam, produced by burning coal. By the 1950s the high-pressure boiler station (now The Elizabeth) was flanked by a low-pressure boiler, a power station and coal silos (now Regatta Wharf) and Engineers’ stores at the bottom of Harris Street.

By the 1950s steam was produced by burning 2000 tonnes of coal each week, delivered on the wharves. Eventually so many ships moored here that a new jetty (Free Wharf) was built, doubling the berthing capacity of the Bay. So vital was this system that CSR was one of few private power stations in Sydney, insulating CSR from industrial disputes and supply outages. The company managed a “steam account” to keep track of power, just as it maintained a “sucrose balance” to control the quality of the sugar it produced.