Elizabeth

Date Built: 2000

Architect: Daryl Jackson Robin Dyke

10 storeys, 44 New York style apartments. Retains original red bricks and art deco facade. Overlooks Johnstons Bay and Pirrama Park. Site of CSR boiler house.

Elizabeth

1880 - 1950

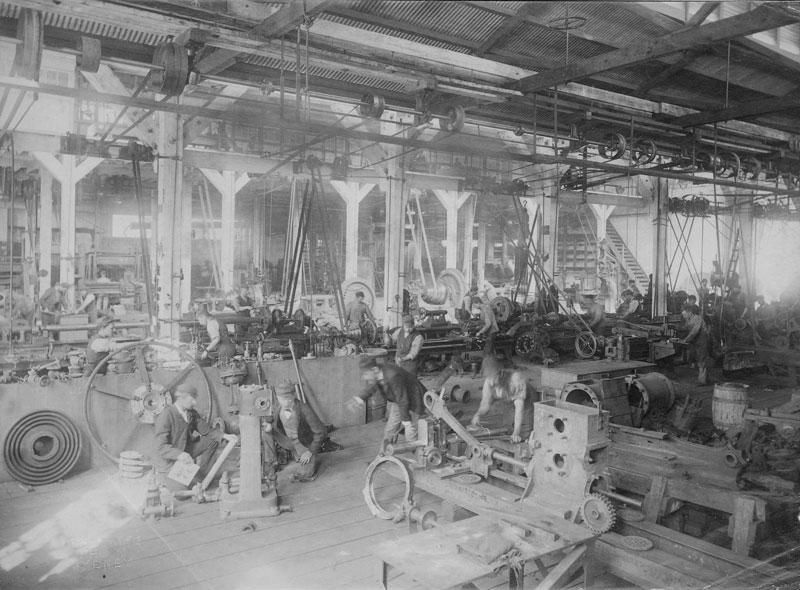

Drawn by Elizabeth Macarthur Bay and its anchorage, CSR’s Managing Director Edward Knox bought land and built a refinery in Pyrmont. This complex opened in 1878. As prices collapsed in the 1880s (triggered by European beet sugar), CSR’s survival was threatened. Science and technology were harnessed, and the new Pyrmont refinery – already state of the art – began an endless series of modernisations.

Raw sugar (98% sucrose) is refined (to 99.9%) to create crystalline white sugar and the many other forms (syrup, treacle, molasses, tablet) in which sugar is sold.

Water, ash, organic matter and other sugars are removed to purify the product and prevent deterioration. These impurities are small but elusive: they require hot-water washing, adding and removing lime, carbon dioxide and bone charcoal, filtering, boiling in a near-vacuum, warm air drying and sieving.

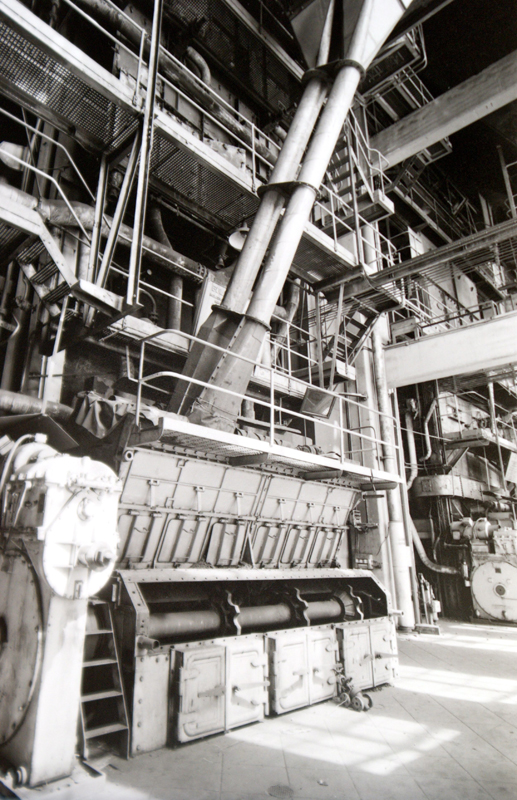

Tirelessly CSR engineers and chemists developed, adapted and tweaked techniques to perfect these processes. But one feature persisted: all processes made huge demands for power. CSR always generated its own. The present Elizabeth was where that power was generated in high pressure boilers. Coal was shipped in to the wharf and stored in silos (on the present Regatta Wharf) to supply these boilers to generate steam power.

When the Pyrmont complex expanded into distilling (from 1901) and caneite (from the 1930s) power became even more important. The war-time production of armaments added to the urgency of preventing any interruption to the power supply. The system was based on steam, produced by burning coal. By the 1950s the high-pressure boiler station (now The Elizabeth) was flanked by a low-pressure boiler, a power station and coal silos (now Regatta Wharf) and Engineers’ stores at the bottom of Harris Street.

By the 1950s steam was produced at 650 lbs per square inch (46 kg per square cm) driving high speed turbines through electric alternators. This operation burned 2000 tonnes of coal each week. Economies and safeguards were constantly pursued, such that (for example) CSR managed a “steam account” to keep track of power, just as it maintained a “sucrose balance” to control the quality of the sugar it produced.

By the 1980s, three Brown-Boveri 6250KVA turbo alternators produced power which was transformed to 415V for factory use. The complex was then one of few private power stations operating in Sydney, insulating CSR from industrial disputes and supply outages.